Multi Pro 1750 662 litre dedicated sprayer

Leading sprayer technology, proven reliability and innovative accessories provide many performance and operational advancements. Every aspect of the spray system has been engineered to deliver unsurpassed spray accuracy, aggressive agitation and faster response time. Consistently delivers desired spray rates in even the most demanding environments.

Multi Pro 1750 with GeoLink® GPS Technology

This smart system knows your precise location. By automatically turning individual nozzles on and off, overlaps are virtually eliminated, resulting in substantial product savings.* You only need to map out your application area once, and the data will be saved for future applications.**

| Agitator | Three side-mounted jet agitation nozzles for full tank agitation. |

|---|---|

| Boom Actuators | Heavy-duty hydraulic lift actuators with nitro-steel plated shafts; 4.4 cm Bore x 25.6 cm stroke. |

| Boom Assembly | 5.6 m (18.5') three-section, triangular truss-style open booms, expandable to 6.3 m (20.5') with optional kit. Eleven nozzle turrets, triple turret-mount, quick-disconnect with diaphragm check valves. Twelve nozzle turrets with optional kit. |

| Brakes | Four wheel hydraulic disc, 2-piston calipers; Front: 19 cm (7.5") diameter rotor, Rear: 24 cm (9.5") diameter rotor. |

| Cooling System | Air-cooled engine. |

| Electrical System | 12-volt battery, 300 cold cranking amps at -18° C. 12-volt, 60 Amp alternator. Dash mounted ignition switch. |

| Fuel System | 18.9 litre moulded Roto-Low Perm tank with 38 mm fill opening, non-vented cap w/tether, mechanical float-type fuel gauge and roll-over valve; carbon vapor canister; mechanical fuel pump |

| Gauges/Instrumentation | Multi-function display (InfoCenter™), analog pressure gauge, mechanical fuel gauge. |

| GeoLink® Capable | Yes |

| Ground Clearance | 13.9 cm |

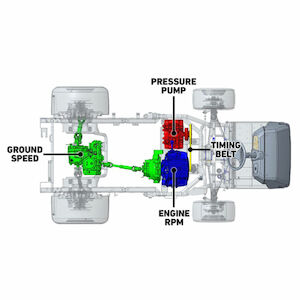

| Ground Speed | Forward: 0 - 11.5 mph Reverse: 0 - 2.5 mph (0 - 4 kph) |

| Height | 2.4 m [with booms folded in cradles] |

| Length | 3.55 m [with booms folded in cradles] |

| Lights | Rectangular 12-volt, 37.5 watt halogen sealed beam headlights. |

| Main Frame/Chassis | High-strength, formed steel rear frame channels welded to steel tubular crossmembers and upper/lower steel tubular structure, ROPS standard. |

| Optional Accessories | CleanLoad™ eductor, fresh water rinse kit, electric hose reel, Pro Foam™ marking kit, Pro Foam™, Ultra Sonic Boom™ kit, covered boom kit, universal sunshade, hand spray wand kit, air induction turbo twin jet nozzles, contact & systemic nozzles, NozzAlert™, GeoLink® Precision Spray System |

| Overall Width | 1.77 m [with booms folded in cradles] |

| Power Train (Engine Description) | Kohler® CH740 Command Series, twin-cylinder, air-cooled, 4-stroke engine, 18.6 kW (25 hp) gross. |

| Rated Capacity | 662.4 litres |

| Seat | Single, high back cushion seat standard with manual position adjustment and seat belts. |

| Solution Tank | Elliptical, high-density, impact-resistant polyethylene with large 41 cm fill well opening; tapered bottom and sump with drain. |

| Sound Level | 86 dB(A) at operator ear under normal operation |

| Spray Controls | Spray pump control switch, agitator jet switch, rate switch, individual boom on/off switches, boom actuator switches, indicator lights on pump, agitation & boom switches, throttle lock, app rate lock-out. |

| Spray Pump | Hardi 364/5.5, 6-diaphragm positive displacement w/ 2.5 cm input shaft; input speed 300~860 rpm, Flow rate of 170.3 L/min @ 2.76 bar (860 rpm). |

| Steering System Description | Fully hydraulic; steering wheel turns, lock to lock: 3.5 |

| Suspension | Front suspension – Double A-Arm with coil over shock; Rear suspension – rigid; rubber tyres. |

| Tires - Rear | 24 x 13.00-12, 6-ply |

| Traction System | Kanzaki / Tuff Torq 3-speed (forward). 1-speed (reverse), mechanical transaxle with differential lock. |

| Turning Diameter | 2.2 m to sprayer centreline |

| Tyres - Front | 20 x 10.00-10, 4-ply, Treadless |

| Valve Actuators | Eleven nozzle turrets, triple turret-mount, quick-disconnect with diaphragm check valves. Twelve nozzle turrets with optional kit. |

| Vehicle Controls | Ignition key switch, choke, headlight switch, optional wireless hour meter, speed lock. |

| Weight | Shipping weight: 997.9 kg, MGVW: 1814 kg |

Select your model year from the options below to view parts & manuals.

**See dealer for Warranty details.